Our easily-operated and reliable test instruments have set worldwide standards for testing carbon products. These test instruments can measure all key properties of carbon materials based on methods approved by DIN, ISO and ASTM standards. 75 % of the world's anode production is monitored with R&D Carbon's test equipment.

In our modern workshop we produce over 50 different test instruments. Before shipment each piece of equipment undergoes several tests such as calibration and cross-checks during the factory acceptance tests to ensure that the equipment is accurate and reliable.

Production

Procurement

Support the supplies of goods and services to deliver equipment in the shortest possible time.

Assembly

Each equipment is built to meet the stringent quality requirements of the Swiss quality.

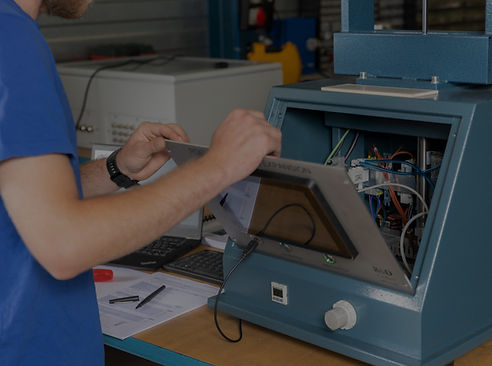

Acceptance Test

Intensive testing are performed during the factory acceptance tests to ensure the accuracy and reliability of test equipment.

Packing

Equipment is packed with great care to be shipped all around the world.

Services

Commissioning

Commissioning is a global process for testing and validating the performance of test equipment to ensure its optimal functioning.

R&D Carbon makes sure that all the systems are installed, tested, operational and maintained, to meet the requirements of in terms of performance, reputability and reproducibility.

Maintenance

Preventive maintenance is a regular and routine action taken on equipment by providing systematic inspection. It consists of parts replacement, cleaning, adjustments, tests and measurements, performed specifically to prevent faults, breakdown or malfunction from occurring.

The main components of the equipment are checked to ensure correct functioning and no defects.

Repair

It can be defined as a task performed to identify, isolate, and rectify a piece of faulty test equipment. The instrument can be restored to an operational condition.

This task can be carried out at the customer or in our workshops if the equipment is returned.

Support

The purpose of a help desk is to fix problems or provide guidance about equipment products such as sample preparation, test procedure, test results and troubleshooting.

R&D Carbon provides help desk support to his customers through various channels such as instant email or phone call.

Training

Our experts are available for training on-site or at our premises.

Development

Engineering

Evolving product and process technology requirements by anticipating customers' demand.

Designing

From sketch to 3d model, technical drawing is used to express ideas.

Prototyping

A draft version of test equipment is built to explore a concept before the final product.